Company Visit at Robert Bosch Semiconductor HQ

The IEEE Young Professionals Germany ExCom organized in cooperation with the Robert Bosch GmbH a virtual company visit at the semiconductor headquarters of Bosch, Germany.

Unfortunately, the worldwide pandemic situation made an onsite visit not possible. Therefore, all registered participants agreed to make this virtual visit and event happen. From the 30 exclusive slots, 23 students and young professionals attended the virtual event. On top 14 participants from Bosch semiconductor headquarter, i.e. top level management, chief experts and human resources completed a great event.

The one-day event started at 9:15 and went until 16:00. In the morning Mirko Hofmann, director of the MEMS design house welcome the attendees and guided together with Mike Schwarz through the program of the day.

The first talk was delivered by Armin Scharping and was entitled “Site presentation and manufacturing area”. The talk gave some insights of the various possibilities of manufacturing available in Reutlingen and in future also in Dresden´s 300mm fab. An impressive video presenting the clean room facilities closed the talk.

Afterwards, Ali Aboosaidi from the IEEE YP Germany AG gave an overview of the activities of the YP in Germany. Organizing events and focusing on exchange/ networking with further YP groups.

The event continued with more insight by Frederik Schrey from the integrated circuit domain of Bosch and gave a talk “ASICs and Semiconductor Technologies for Bosch Systems”. Here, Mr. Schrey concentrated on an portfolio overview and the future possibilities with the 300mm fab in Dresden.

After the overview Sebastian Strache continued with “Bosch Power Semiconductors and Modules”. Mr. Strache introduced the power semiconductors and SiC for volume production. He also highlighted, that ongoing research is fulfilled by the Corporate Research Department. A few questions came up on examples. Here, it was emphasized that OEMs by i.e. inverters from Bosch for electronic cars.

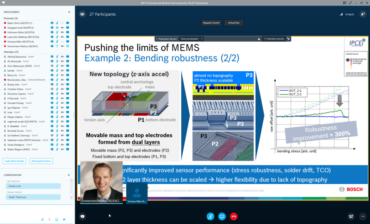

Vice President Dr. Markus Sonnemann presenting “MEMS – enabling technology for future mobility solutions pushing the limits of MEMS”.

The day continued with a talk of Markus Sonnemann, Vice President and Head of the predevelopment of MEMS, followed with the title “MEMS – enabling technology for future mobility solutions pushing the limits of MEMS”. Here, Mr. Sonnemann gave a lot of examples of sensor improvements by technology and the success of predevelopment.

Finally, the morning session ended by presentations and experiences of the human resources director Florian Schueller and Ulrich Baehr, a former Bosch PhD student. Both shared insights of their Bosch career and offered also entry opportunities. Here, a lot of Q&A made an interesting exchange between employees and students/young professionals.

The afternoon session started with a talk entitled “MEMS Technology”, given by chief expert Heiko Stahl. Mr. Stahl offered various technology examples and insight and processes which enabled different applications which are state of the art today. Furthermore, he concentrated on the needs, where are the hidden aspects and needs to enable MEMS for mass production.

It followed a session of workshops and presentations with possible job advertisements.

Here, Tobias Hanke from the wafer level test development gave an overview of the custom development for MEMS technology in the talk “MEMS wafer test”. Various examples were shown, which emphasized that MEMS are no standard in various domains and how to tackle test equipment and test conditions.

Afterwards, Mirko Hofmann, director of the MEMS design house, gave a talk entitled “MEMS Design House – Design & Simulation”. Mr. Hofmann concentrated on the principal transducer design and optimization. He highlighted the challenges of tolerances, cross coupling and environmental influences, which need to be considered during the design phases until the mass production caused by the impact of packaging.

Here, Ronald Gampp the director of the packaging department gave a talk “MEMS Packaging”. He gave more insights on the main concern of mechanical stress induced on the MEMS element, which itself is mechanics. He gave some examples, i.e. on laser dicing and automized pick up tools, to overcome these challenges.

After the various insights in technology, Matthias Laemmlin from Bosch Sensortec gave a talk on “MEMS Sensors for Consumer Electronics”. Mr. Laemmlin showed the new solutions of smart sensors, including embedded algorithms for artificial intelligence for sensors. Furthermore, he gave an overview on the applications of sensors nowadays.

Finally, Josef Goeppert, director of power semiconductors and modules, offered more insights in power electronics and electrical drives which can vary from a few kilowatts up to several megawatts. Also, he concentrated on the SiC development in Reutlingen and showed finally an impressive video of overload failures during testing and how to actively handle short circuit overload.

The event ended with some final conclusion and a thank to all participants and presenters for their active contributions and questions during the day.